Steel Strapping

Steel Strapping is one of the most commonly and widely used banding materials. It boasts exceptional strength and low elongation making it an optimal choice for large loads. While it has many advantages, it has a few disadvantages such as cost as the main driver.

Steel Strapping is often used in heavy construction as well as banding of steel sections such as tubes, pipes, coils and many more manufactured products.

There are three main types of seals for use with steel strapping:

-Lap Over Seals

-Snap On Seals

-Wing Clip Seals

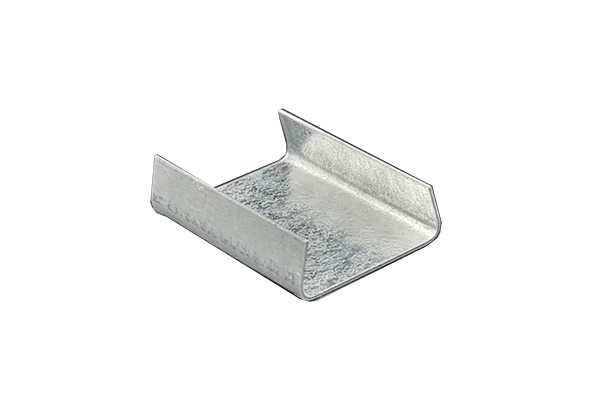

Lap Over Seals

Lap Over Seals are used in conjunction with a separate tensioner and sealer, although they are also compatible with some combination tools. Their main application is in the use of a heavy-duty solution involving irregular shaped stock such as round tubing and irregular-shaped packs.

They are available in various widths from 13mm to 32mm and lengths from 25mm to 57mm.

Snap on Seals

Snap On Seals are used in conjunction with a separate tensioner and sealer.

There are two types, Open Seals and Semi-Open. They maintain strap alignment prior to tensioning the strap and are placed on the overlapping strap ends during or after tensioning. These Heavy Duty Snap On Seals are

predominately used on flat surfaces.

They are available in various widths from 13 to 19mm and lengths from 28mm to 32mm.

Wing Clip Seals

Wing Clip Seals (also known as Knock Overs) are used in conjunction with both a tensioner and a hammer. They are used for lighter work than both Lap Over Seals and Snap on Seals.

They can be used either on flat or rounded surfaces. Once the correct tension is made, the wings of the seal can then be knocked down with a hammer.

They are available in various sizes of 13 to 25mm.